Permeation Test Cell for Dual Application |

|||||||||||

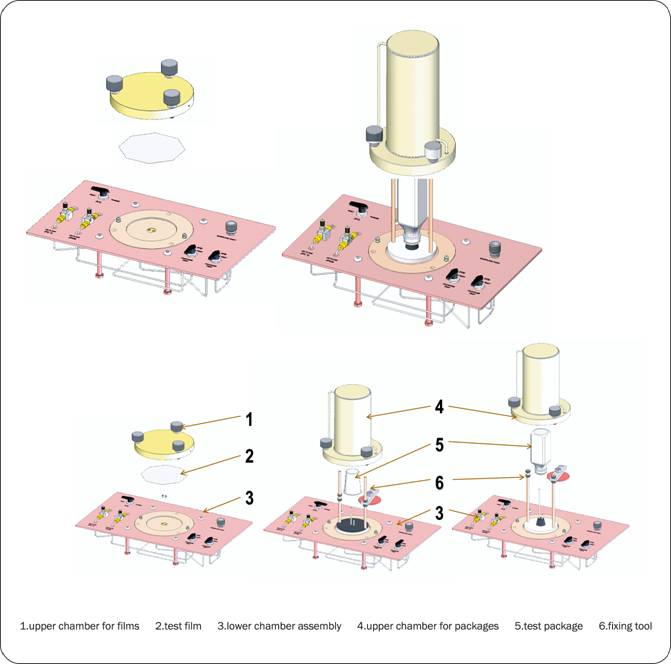

Background Permeation cell assembly

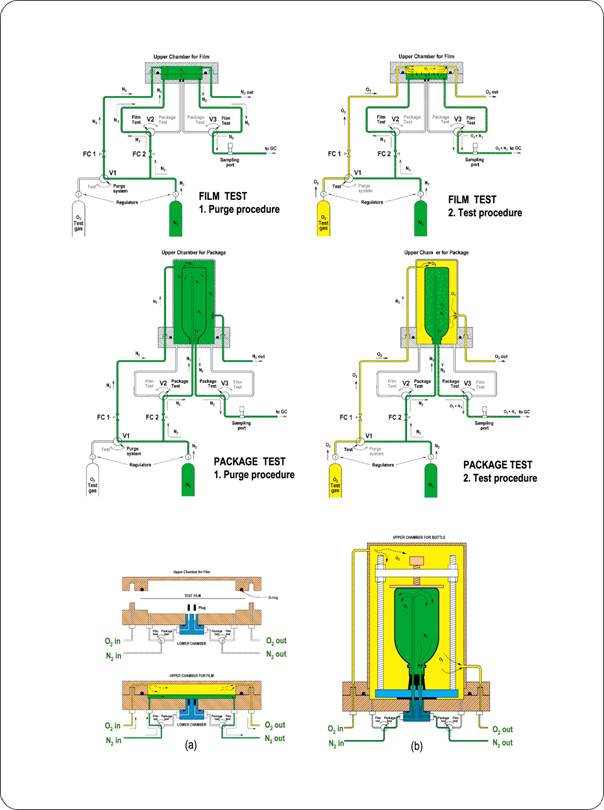

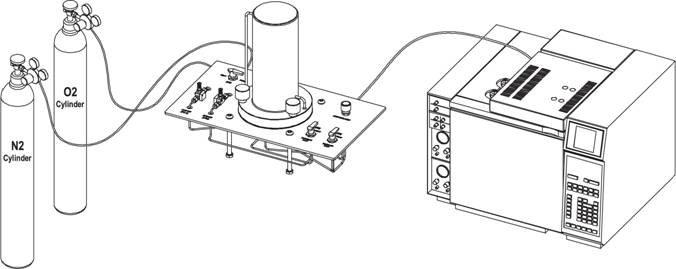

Gas flow assembly: It is based on the isostatic principles described in ISO 15105-2:2003(E) which is specific to flat film samples and ASTM 1307-02 and Loudenslagel and William (1970) specific to preformed packages.

|

|||||||||||

| คณะผู้วิจัย : Ngamtip POOVARODOM1 and Chackapan NGAOWTHONG2 1Department of Packaging Technology, Kasetsart University. 2Department of Design and Production Technology for Agricultural Industrial Machinery, King Mongkut’s University of Technology North Bangkok Prachinburi. Thailand. Tel. 0-2562-5054 |